TETRISTACK FOR PAILS AND BUCKETS

MODULAR ROBOTIC PALLETIZER FOR PAILS AND BUCKETS

PERFECT PALLETIZING SOLUTION FOR CYLINDRIC CANISTERS. Tetristack is a robotic palletizing machine that features Fanuc M-410iC/185 robot with an end-of-arm tool that can handle buckets up to 70lbs. One infeed conveyor delivers the pails to the orientation station. Pails are oriented and collated in groups of three in a manner that saves pallet space. The pallet is manually placed on one of two adjustable docking stations. The robot places the pails on the pallet, arranging them in the required pattern. The pails are stacked in two layers. The full pallet is manually removed for further processing.

PAIL PALLETIZING PROCESS

PALLET

FEEDING

The pallet is manually placed on the adjustable docking station.

ORIENTATION & COLLATION

Pails are oriented and collated in the groups of three in a manner that saves pallet space.

PATTERN

FORMING

The Robot arranges pails in a required pattern for optimal pallet space use.

LAYER

FORMING

When the first layer is formed, the robot places another layer on top of the first one.

PALLET

DISCHARGE

Once completed, the full pallet is manually removed for further processing.

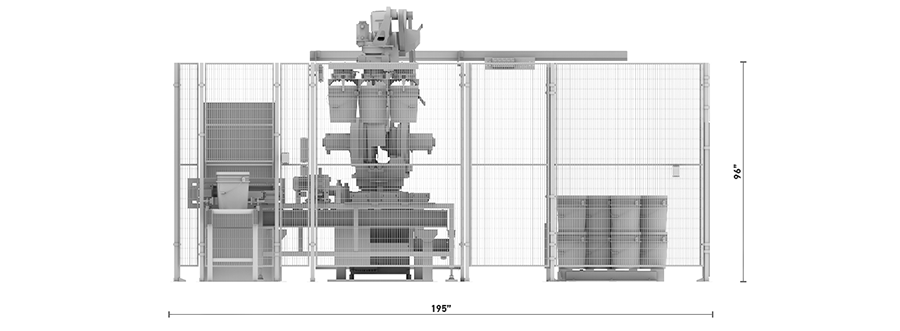

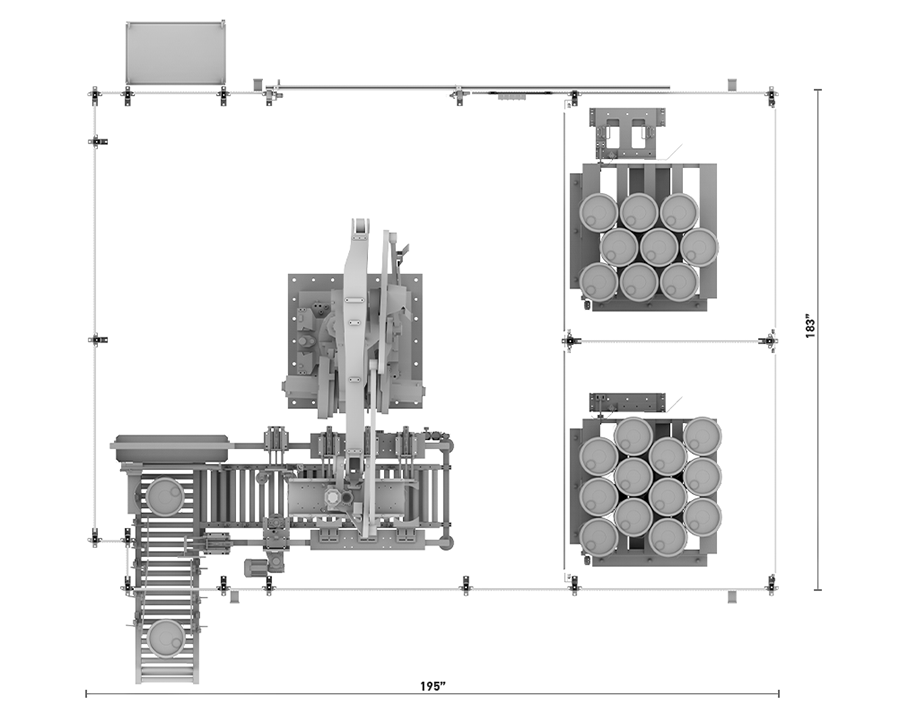

DIMENSIONS

ADDITIONAL INFORMATION

MULTI-PATTERN PAIL ORIENTATION

PRECISE PAIL PLACEMENT

Tetristack features the Multi-Pattern Pail Orientation system, allowing you to choose how the pails will be arranged on the pallet to maximize the pallet-space use. The pail orienting and collating station forms the groups of three pails, arranging them under a specific angle, so the canister handles don’t collide. Recipe formulation and adjustments are performed via the Fanuc Teaching Pendent. The Robot picks and places pails into one of two available patterns: 3x3x2 and 3x4x2. Besides pails, this orienting system can also handle buckets, drums, and other cylindrical containers.

TECHNICAL

SPECIFICATIONS

| GENERAL OPTIONS | Slip/tier-sheet rack; Zero pressure product in-feed conveyor. Full line integration service |

| PRODUCT IN-FEED OPTIONS | Case erection, Case loading, Case sealing, Case closing, Labeling, Vision inspection, Check weighing, Rejection |

| END EFFECTOR OPTIONS | Pail tool, Clamp tool, Fork tool, Case/bag tool, Vacuum tool |

| PALLET OUT OPTIONS | Buffer conveyors and Stretch wrapper |

| PALLET IN-FEED OPTIONS | Pallet dispenser |

| OPTIONS | Pallet Dispenser, Slip Sheet Dispenser, EAOT options: Bag, Case |

PALLETIZING VIDEO

BENEFITS

TWO PALLETS SIZES

PAIL ORIENTATION STATION

TWO PALLETS STATIONS

MULTI PATTERN PAIL ORIENTATION SYSTEM

HEAVY LOAD ROBOT EOAT DESIGN